Handling Precautions

Handling Precautions

- The display panel is made of glass and polarizer. As glass and polarizer are very fragile to be damaged. It tends to become chipped during handling especially on the edges. Please avoid dropping, jarring, pressing. Do not subject it to a mechanical shock by dropping it or impact.

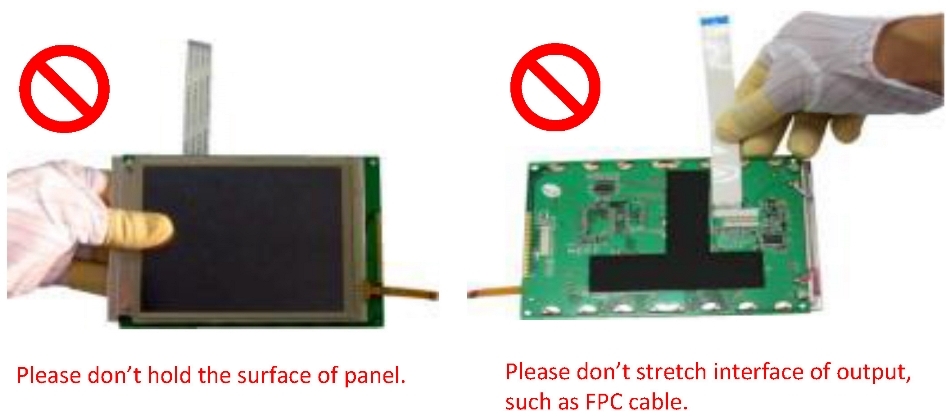

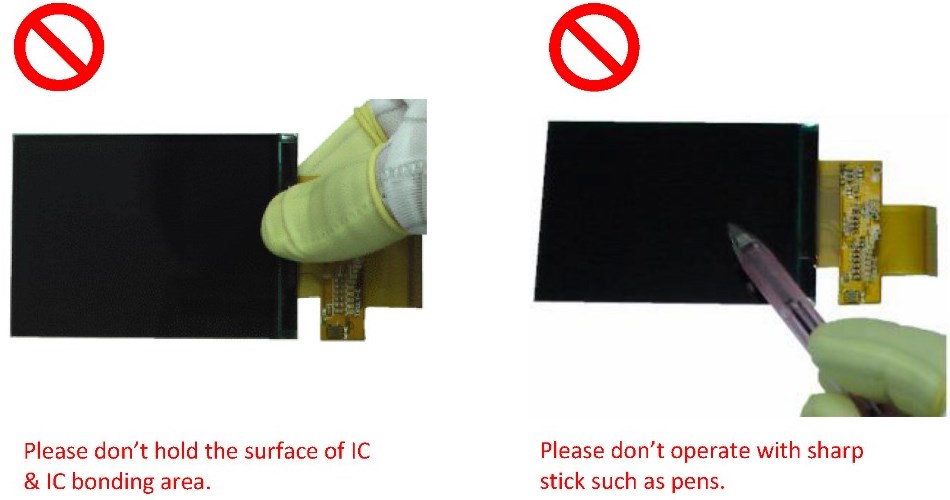

- Do not apply excessive force to the display surface or the adjoining areas since this may cause the color tone to vary. Do not touch the display with bare hands. This will stain the display area and degraded insulation between terminals (some cosmetics are determined to the polarizer).

- The polarizer covering the display surface of the LCD module is soft and easily scratched. Handle this polarizer carefully. Do not touch, push or rub the exposed polarizers with anything harder than an HB pencil lead (glass, tweezers, etc.). Do not put or attach anything on the display area to avoid leaving marks on it. Condensation on the surface and contact with terminals due to cold will damage, stain or dirty the polarizer. After products are tested at low temperature they must be warmed up in a container before coming in to contact with room temperature air.

- Do not stack LCD modules.

- If the display is damaged and liquid crystal substance leaks out, be sure not to get any in your mouth. If the substance contacts your skin or clothes, wash it off using soap and water.

- If the display surface becomes contaminated, breathe on the surface and gently wipe it with a soft dry cloth. If it is heavily contaminated, moisten cloth with one of the following solvents.

- Isopropyl alcohol

- Ethyl alcohol

Do not scrub hard to avoid damaging the display surface. - Solvents other than those above-mentioned may damage the polarizer. Especially, do not use the following.

- Water

- Ketone

- Aromatic solvents

Wipe off saliva or water drops immediately, contact with water over a long period of time may cause deformation or color fading. Avoid contact with oil and fats. - Exercise care to minimize corrosion of the electrode. Corrosion of the electrodes is accelerated by water droplets, moisture condensation or a current flow in a high-humidity environment.

- Install the LCD Module by using the mounting holes. When mounting the LCD module make sure it is free of twisting, warping and distortion. In particular, do not forcibly pull or bend the IO cable or the backlight cable.

- Do not attempt to disassemble or process the LCD module.

- NC terminal should be open. Do not connect anything.

- If the logic circuit power is off, do not apply the input signals.

- Since LCM has been assembled and adjusted with a high degree of precision, avoid applying excessive shocks to the module or making any alterations or modifications to it.

- Do not alter, modify or change the shape of the tab on the metal frame.

- Do not make extra holes on the printed circuit board, modify its shape or change the positions of components to be attached.

- Do not damage or modify the pattern writing on the printed circuit board.

- Absolutely do not modify the zebra rubber strip (conductive rubber) or heat seal connector.

- Do not touch the zebra strip nor modify its location

- Except for soldering the interface, do not make any alterations or modifications with a soldering iron.

- Do not drop, bend or twist the LCM.

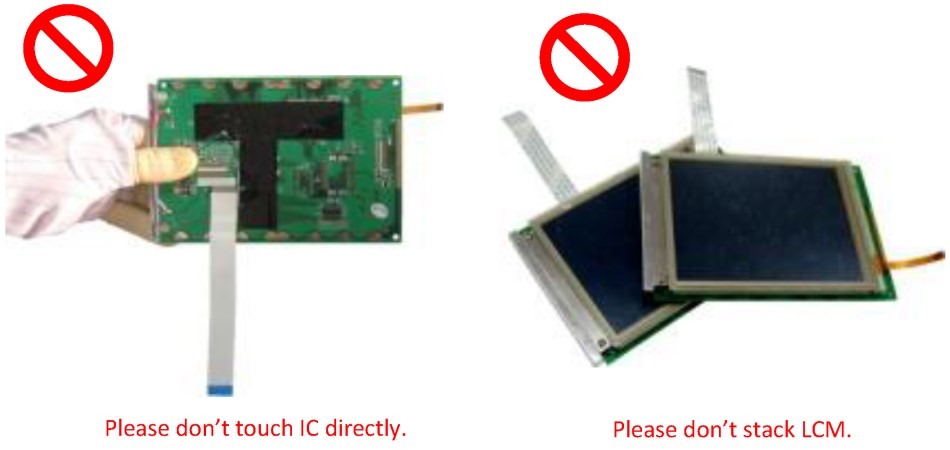

LCM is easy to be damaged. Please note below and be careful for handling.

- Correct handling :

- Incorrect handling